Air-Casting

Wearable Menstrual Pain Relief

Right now, over 750 million people are on their period, and nearly half will experience pain that last a few days.

We wanted to create a new product to address this problem, because none of the existing products on the market were designed to be worn discreetly on a moving body.

So we’ve asked folks what they need. Our survey is receiving new data every day on the experience of menstrual pain (Take our Survey). Preliminary results indicate pain is primarily located on the lower abdomen and lower back. People find relief using Tylenol (patented in 1955) as a monthly dose of painkiller, and using heat; often a hot bottle water (patented in 1903).

We realised that menstrual pain is a historically underrepresented market for design solutions, and we thought it was high-time for some innovating.

So we got to work. Katherine Porter, Robin Linton, Graham McLaughlin, and Charlie Katrycz worked to design a new solution.

We wanted something soft and wearable, that provided heat, directly to the shape and location of menstrual pain.

We’ve created Undu: Wearable menstrual pain relief. Undu uses the Loonskin technology patented by Charlie Katrycz (2019) to produce a soft, wearable, seamless, well-shaped heat pack. A modern solution that leverages the age-old use of heat.

We fill the packets with thermal gels - the kind you can heat up in a microwave or pot of hot water, or cool down in a freezer. We are also experimenting with more advanced gels and liquids to fill the packets with: sodium acetate solutions can provide long lasting heat through phase-change. We are still prototyping this technology and working with testers to determine what works best.

Loonskin

The air-casting technique has a long history here at Loonskin Labs. A decade ago, Charlie wondered what if materials could organize themselves to grow into biological shapes like lungs, trees, and veins? We developed a brand new technology that enables just that. With our patented platform (allowed Spring 2019), we can grow artificial circulatory systems and branched hollow networks into an array of materials. We are piloting projects that apply this technology to heat capture and wearable climate control, water purification, wound treatment, and soft robotics. Scroll down to learn more about this revolutionary manufacturing process, and the history of our efforts to develop the new method.

Viscous Fingering Process

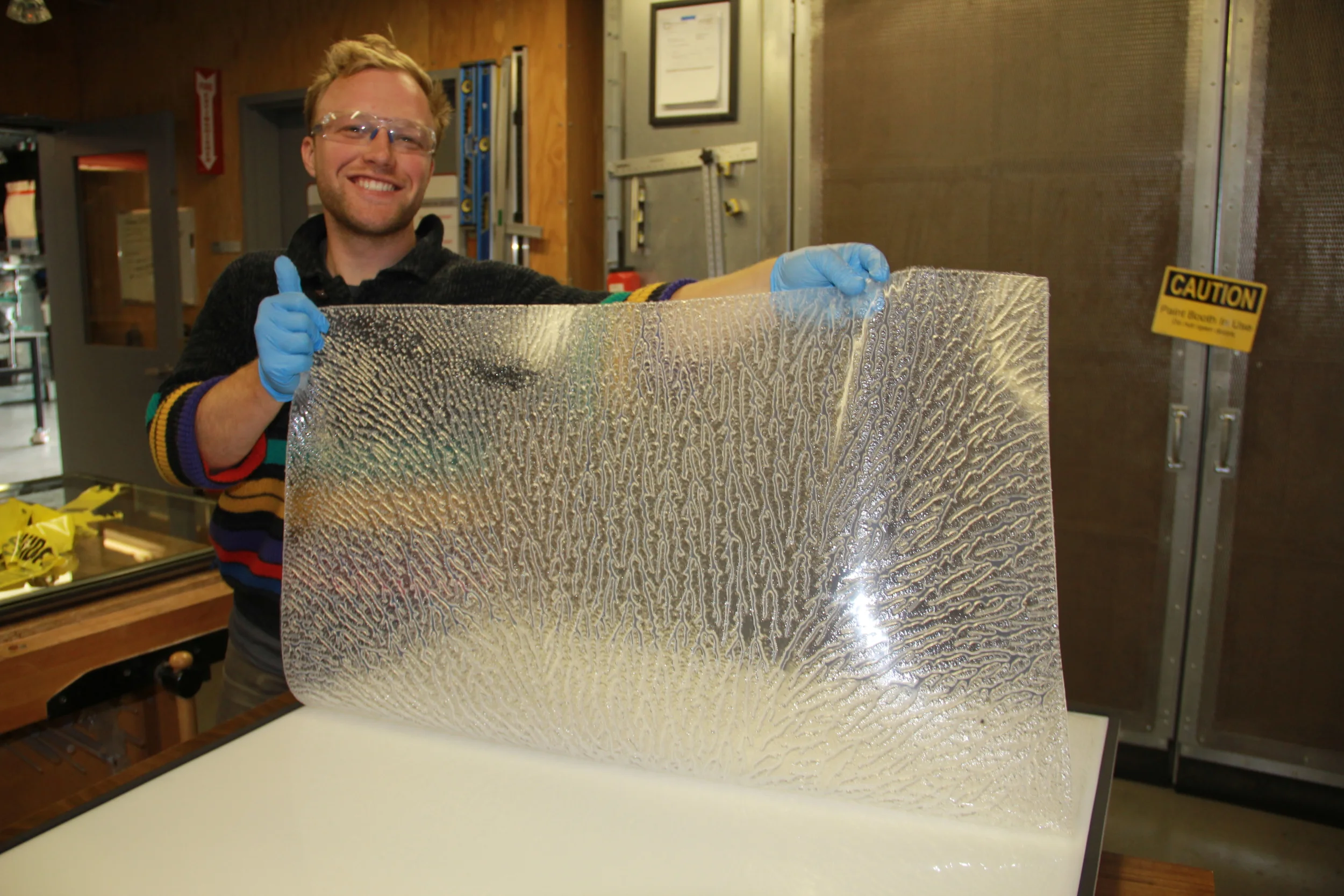

Growth is not limited to biology. Material can generate creative and living outputs. Here Viscous Fingering is used to generate hollow pathways within liquid silicone. The Silicone cures, and an inflatable network is the result. Fluid can be transmitted through these channels, to move heat, or deliver nutrients. It can be inflated with pressurized air to create rigidity - soft robotic actuators, body armor, and light weight wings.

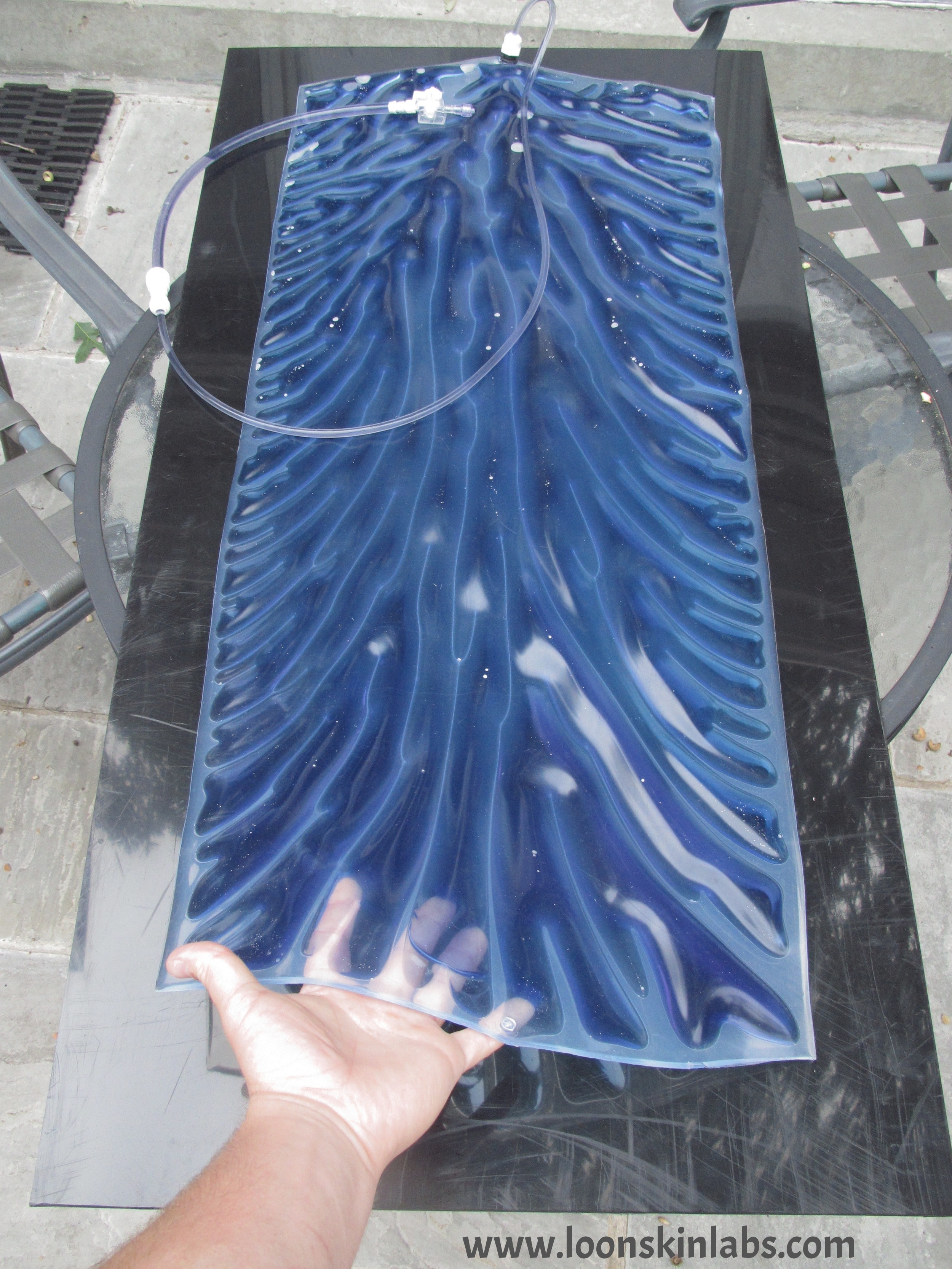

Thermal Fluidic Window Installation

The installation of this large water-filled membrane was completed for Autodesk's 2016 Spring Showcase. The fabrication of the sheet was completed at Pier 9 in San Francisco. The sheet has water periodically pumped into it, absorbing incoming sunlight and increasing the thermal inertia of the window. By filling the membrane with a fluid that matches the refractive index of the silicone, the sheet can become transparent. Colour can also be introduced to a stained-glass effect.

10,000 Fingers

The number of channels grows exponentially during the injection process. The result is a highly branched, densely distributed network of hollow channels within a solid silicone membrane

The Channels

The hollow channels in this image are on average about half a centimeter in diameter. They are represented by the dark branched network. The light branched network is the negative of the hollow channels. It is solid silicone.

Solar Heat Capture Prototype

Here is an early stage prototype made by Loonskin Labs in flexible silicone. Water is injected into the channels and the sheet covers a black surface to maximize the absorption of solar energy. This prototype is currently undergoing testing to determine effectiveness, durability, and practicality of its use in heating and purifying water using sunlight.

Heat Transfer Demonstration

In this video we see water at a temperature of 48C being pumped into the membrane, which is in contact with a wooden surface, both at 20C. The wooden surface is painted with a pigment that changes from blue to orange at 30C. Three liters of water is pumped in and heats the surface, which can be observed in the change in colour of the substrate. This is a simple demonstration of the ability for the membrane to rapidly transfer heat to and from surfaces.

Roll-On Rooftop Covers For Water Purification

These mats are flexible, durable membranes made from UV-transmittable silicone, or recycled PET plastic water bottles. The mat gets connected to a water source - a hand or electric pump - and a storage tank for clean drinking water.

Using sun's UV light to disinfect the water is an effective practice used in developing countries, and is known as the SODIS (solar water disinfection) method. The suns ultraviolet radiation combined with heat kills harmful pathogens to make water safe for drinking.

Our design allows faster purification times by exposing thin layers of water to the sun. An added benefit is that the sun's heat is not absorbed by the roof of the house, but instead by the water. By cooling the top of the house this way, convection currents are promoted, circulating fresh air into the residence.

The hot water can then be stored for later use for drinking, cooking, cleaning, or bathing.

Solar Panel Cooling And Heat Recovery

Solar panels are prone to overheating, which dramatically reduces the efficiency of solar energy capture and speeds up the deterioration of the panel.

Using Loonskin membranes to cool the panel allows for the excess heat to be captured in water, and used as a hot water source for the building - increasing the panel's efficiency, and its life expectancy, while decreasing the demands of the energy harvested to do things like heat household water.

Biomedical Applications for OneStart Americas 2015 Semi-Finals

Our team finished as Semi-Finalists in the world's largest biotech startup competition for our Loonskin concept applications of treating wounds and preventing bedsores.

Wound Treatment

This child has a large keloid scar that affects the majority of their chest. The scar tissue is rigid and inelastic. A current method for treatment is to administer a sheet of silicone during the healing process to trap moisture, and massage the tissue. We believe that our delivery mechanism could greatly improve on the existing technique. Our skins can deliver coolant to sooth the skin, massage the tissue through pulsing, even while the patient slept, and they can be customized to the shape of the injury, so full coverage can be achieved. We also see the potential for these membrane to act as a delivery system for nutrients, oxygen, or stem cells, for the treatment of many kinds of surface wounds.

Pressure Ulcer Prevention

Bed Sores result from a lack of blood perfusion to the skin. This happens often in elderly populations where mobility is an issue. Long duration of high pressure on the underside of the body while laying in a hospital bed or wheelchair cause skin to deteriorate rapidly and form open wounds called pressure ulcers. Current solutions are expensive (upwards of $30,000 for a hospital bed) they are heavy and bulky, and cumbersome to move around a hospital. They are also loud. Our solution is to roll on a bed cover with ingrown channels to alleviate pressure. Our membranes can pulse with fluid to stimulate circulation, and regulate the temperature of the skin to promote healthy conditions and prevent bedsore development. Our solution is cost effective and simple to implement. Whether on a bed, wheelchair, or in your shoe (foot ulcers are common among diabetics), we can rapidly customize the size and shape of our membranes to meet the needs of the patient. The image on the right shows a channel system that was created using the imprint of my foot. Never before have we had this ability, to grow structured channels into the shapes of applied pressure.

Pneumatic Cushion

The surface of contact between a body and a bed can dramatically affect the survival rate of patients who have limited mobility. By inflating and deflating this membrane periodically underneath a person who is bed bound, tissue may be stimulated to maintain healthy blood profusion and prevent the development of ulcers.

Cooling The Body

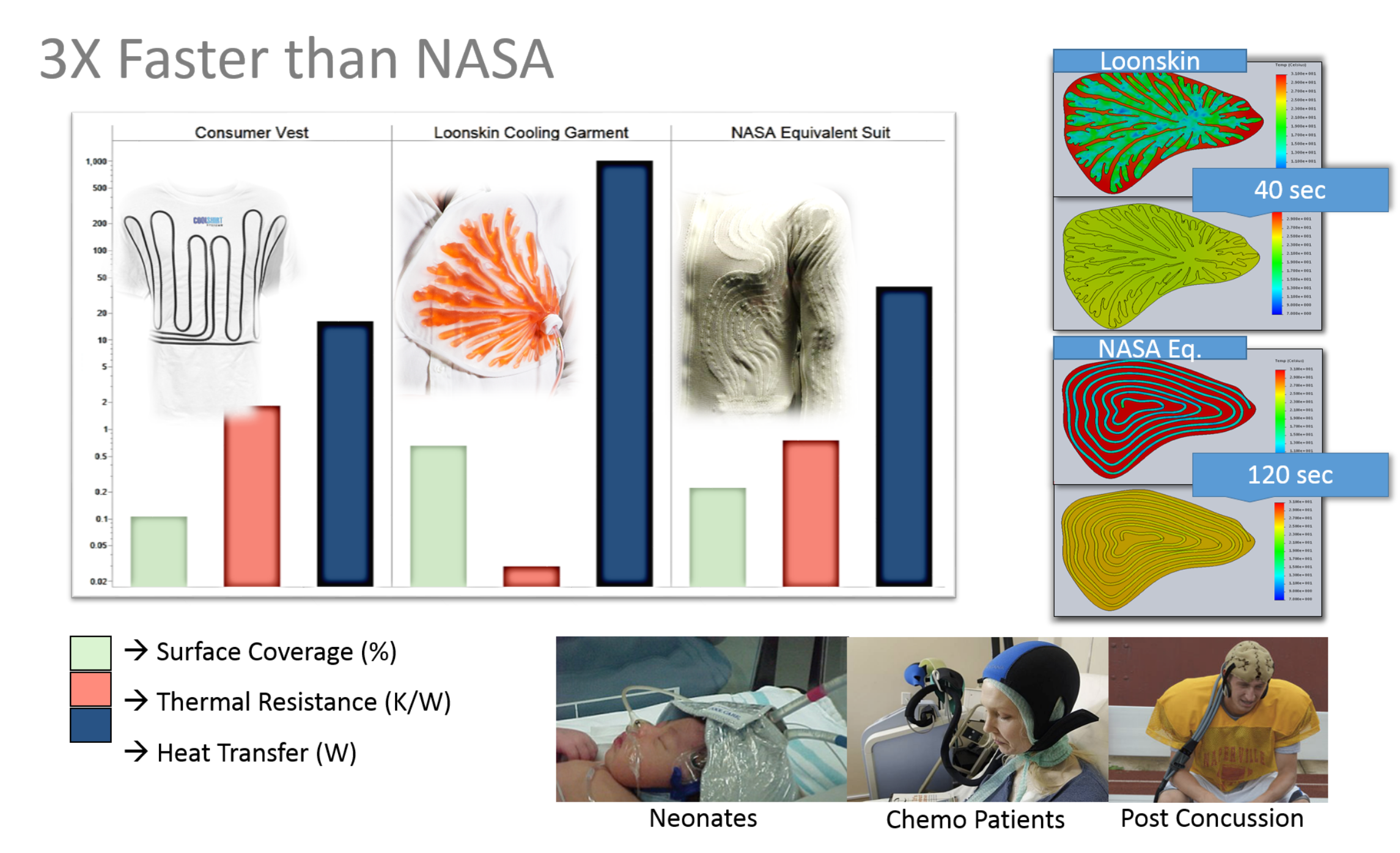

Current methods employed by NASA in their liquid cooled garments' design require 46 tubes of combined length over 90 meters to be woven into the garment. The long lengths of tubing create uneven temperatures, require greater energy to pump liquid through, and the anti-kink hosing is bulky with a lower coefficient of heat transfer. As a result, suits require liquid to be chilled to low temperatures for the desired effect.

Our skins, shown right, are radial in delivery, broad and shallow, and are separated from the shirt by a membrane only 1/5th of a milimeter thick. Only 100 milliliters of fluid are required to cover 1/10th of a square meter (~1 square foot) and this can be further reduced in future prototypes. Computer simulations showed that our design can cool the surface 3x faster to reach a lower equilibirum than NASA's.

In the middle we see an Ebola worker undergoing decontamination. In hot climates, emergency workers are at risk of rapidly developing heat stroke, and so they must change out of their suits regularly. Unfortunately this is when they are most vulnerable to contracting Ebola. Liquid Cooling Garments have traditionally been too expensive to employ in such situations. Our product is easily manufactured and could be implemented to increase the time between changing out of suits, and decrease infection among practitioners.

Effective Heat Exchanger

A comparison (from left to right) of liquid cooling garments: consumer-grade cooling shirt worn by motorcyclists and race car drivers, our membrane, and NASA's suit.

Our preliminary simulation results shows that we are able to drop a copper surface's temperature to equilibrium three times faster than an equivalent NASA design. The reason is an increased surface area coverage, and decreased thermal resistance due to our extremely thin membrane. Without accounting for convection factors, our product's rate of heat transfer could be as much as eight times higher than the NASA tubing.

With many emerging medical applications for cooling therapy including prevention of neonatal encephalopathy, hair-loss prevention in chemotherapy, and concussion therapy, the potential application of our technology on earth alone is vast.

Structured Balloon Rooms - Rigid Inflatable

Inflating these membranes with air under pressure creates rigidity and causes deformations in the membrane that can be programmed to desired need. Here we see the same membrane as shown in the rooftop solar water heating application, but filled with air instead of water. The membrane curves under pressure and creates a rigid, structural half-cylinder. A structured balloon on large scales could be extremely lightweight, provide excellent insulation, self-assemble under inflation, and allow for diffuse natural lighting.

Thermal Window Blinds & Stained Glass

The shapes created using our process are reminiscent of living things. Indeed biophilia played a significant role in Charlie's fascination with the pattern forming process, when he first discovered it during kitchen counter-top experiments as a physics undergraduate student at McGill University.

While embedding these membranes within other materials for wearable or industrial applications should prove highly useful, applications where the inner beauty of the shape is showcased should be considered. One example of such a use, building on Benjamin Hatton's work, is in vascular sheets for regulating insolation through windows. Coloured fluid could be used to trap sunlight and prevent it from heating up the room. The water could by cycled through to a heat exchanger external to the building to dissipate the heat.